The hidden engineering design secrets of the 12 pounder Gribeauval cannon

Sunday, 18th March 2018

The hidden engineering design secrets of the 12 pounder Gribeauval cannon

Speaking from experience of one who has a very uneducated “cannon” eye, despite the fact that I’ve lived with an expert on everything “cannon” for the past 30 years.

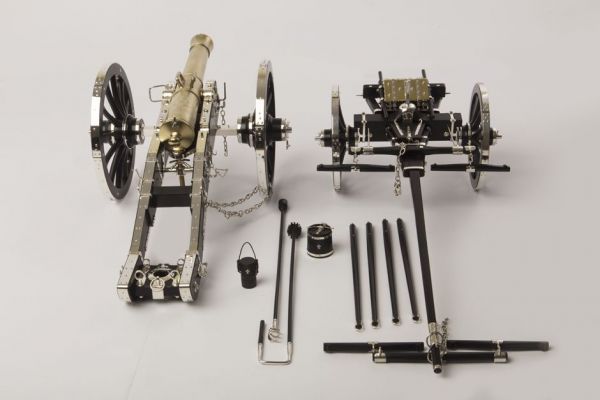

On hearing Zane Palmer provide insights to a prospective buyer relating to the beautiful, sterling silver, art piece in the 12 pounder Gribeauval cannon and Limber that they were discussing, I was fascinated to find out more behind the actual design.

Here are some of the interesting details they discussed.

What is a cartouche?

It is a usually a wooden device used to carry ammunition between the limber and the gun and to store ammunition on the battlefield.

What are the safety features of the ammo pouch/cartouche?

The cartouche lid is fixed to the device with a rope handle. When the ammo pouch is carried (that is picked up by the rope handle), the lid will automatically fall into a closed position, thus preventing an errant spark igniting the ammunition it is carrying during the heat of battle.

How was the charge made up for the 12 cannon?

The charge was made up in 3 segments. The cannon ball was fastened to a wooden sabot which was fastened to a canvas bag containing the measured amount of cannon grade black powder. For ease of handling, these 3 sections were combined into one unit.

What is the purpose of a worm rod?

A worm rod was used to remove any debris inside the barrel after firing. Debris most often consisted of burning embers from the canvas bag that were forced back into the barrel by the explosion.

Why does the lid fall into the bucket when opened?

To ensure any remnant burning embers in the barrel were well and truly extinguished, it was essential that the barrel was cleaned out with a wet sponge/brush between shots. In order to carry this out, they needed to have access to a bucket containing water. As the cannon often travels over rough terrain, the bucket needs to be closed with a lid to prevent the loss of water. In order to prevent the loss of the lid during transportation or the battle, the design of the lid is such that the lid cannot be separated from the bucket when the lid is opened. This is achieved by the lid dropping into the bucket on opening.

Why is the hole in the top of the bucket narrower than the sponge/brush?

The hole in the top of the bucket is designed to squeeze excess water from the sponge/brush as it is removed from the bucket. This ensures that the sponge or brush isn’t too wet when used to sponge the barrel of the cannon after each shot is fired.

Why should it not be wet inside the cannon barrel?

A wet sponge/brush inside the cannon barrel will leave a little puddle of water in the bottom of the barrel and when the next charge of gunpowder is rammed home, the canvas will absorb the moisture and wet a portion of the powder inside the bag. When this charge is fired the wet powder will remain smouldering in the bottom of the barrel and could cause the next charge to ignite prematurely which would have detrimental effects to the poor loader.

What are the 4 round wooden rods used for?

These are traversing rods, that slip through the I-bolts on the back transom of the cannon. These are typically used to aim the cannon left and right. The little silver lug locks it in place to stop the rods pulling out of the I-bolts when running the cannon back into firing position.

The 2 remaining traversing levers slip through the handles on the side of the cannon (one on each side) and allow the crew flexibility to manoeuvre the cannon into a firing position.

Why is it that there are 2 positions on the carriage for the cannon trunnions?

When the cannon is being transported and the limber is in position then the cannon barrel is placed in the rear depressions and the cap squares used to retain the barrel in position. This allows for even weight distribution between the axles of the limber and the cannon carriage.

When the cannon is prepared for action, the barrel is moved to the front depressions and secured in place with the cap squares.

What is the purpose of the small chains with the hooks on the end found on the front of the cannon?

Similar to a “Strong Man” pulling a truck with a strong leather belt around his middle, a member of the gun crew could attach the hook on the end of the chain to a leather belt around his middle in order to pull and manoeuvre the cannon into a firing position or get it out of the mud etc.

Why are there loops on top of the cannon barrel?

These were known as dolphins (not the swimming kind!!) and were used to lift the cannon barrel with a lifting gin.

How many wooden parts are there in a wheel?

1 wooden hub, 12 spokes, 6 fellows, 6 fellow dowels, 24 wooden wedges make 49 wooden parts in total.

What should I know about the construction of the wheel?

To my great surprise there are many ingenious engineering features built into the design of a wheel. Get ready to share some design secrets of the pre-industrial revolution engineers! And here I thought it is just another round wheel!!

The wooden parts of the outer wheel consist of 6 fellows (curved pieces of wood). Each fellow has 2 spokes that locate in to a central wooden hub.

The fellows are joined together with a wooden dowel, and the dowel is locked into place with a wooden wedge into each end of the dowel. The end of the spokes protrudes through the end of the fellows and are each locked in place with a wooden wedge.

This was strong enough to support the mass of the cannon but to protect the wood from the stones in the road, 6 metal strips were placed around the outside of the fellows. These were held in place by 2 long bolts (one at each end of the metal strip), bolted through the fellow.

8 Metal nails were also used to secure each metal strip. The strips are known as streaks. These nails presented their own engineering challenge as they had a tendency to split the grain of the wood thereby weakening the wheel. To counteract this a metal bar was rivetted through the sides of the fellows preventing the fellow from splitting and that is why there are 6 metal bolts through the side of each wheel.

Why only 6 bolts through the side of a wheel and not 12?

Interesting question! You might note that the streaks meet in the middle of a fellow and not where the fellows are joined. Why would that be? (Quite correct!) The wheel is weakest where the fellows are joined on a horizontal level and could not withstand being further compromised by nails driven in vertically from the top of the wheel which is why the streaks meet in the centre of the fellow.

In later years the streaks were replaced by one solid tyre which was shrunk into position negating the need for the 6 rivets to strengthen the fellows.